DAS is aimed at digitally objects surfaces recording – “virtual” objects creating – and saving them into the DB.

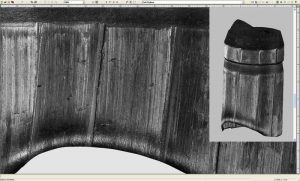

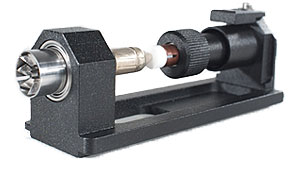

DAS is based on specifically designed and patented (№2130628RU, №2155378RU, №2174251RU, №63556RU, №63478RU) scanning device performing digital “frame-fragment” input of the object under examination image into the DB. The image of a bullet side surface or cartridge case bottom is recorded by “bands”. At that bullet rotates on its axis but cartridge case displaces perpendicular to the optical axis of the scanning device.

DAS is based on specifically designed and patented (№2130628RU, №2155378RU, №2174251RU, №63556RU, №63478RU) scanning device performing digital “frame-fragment” input of the object under examination image into the DB. The image of a bullet side surface or cartridge case bottom is recorded by “bands”. At that bullet rotates on its axis but cartridge case displaces perpendicular to the optical axis of the scanning device.

The device is equipped with a system of auto focusing, convenient detachable universal cassette for fixing objects under examination, by four-sided illumination to reveal the micro relief of all group of traces as for bullets (primary rifling marks, secondary rifling marks (lands), grooves marks) as for cartridges (firing pin marks, breech face marks, ejector marks, etc.).

The device is equipped with a system of auto focusing, convenient detachable universal cassette for fixing objects under examination, by four-sided illumination to reveal the micro relief of all group of traces as for bullets (primary rifling marks, secondary rifling marks (lands), grooves marks) as for cartridges (firing pin marks, breech face marks, ejector marks, etc.).

All recording processes are fully automatized.

DAS performs with all existing handgun firearm systems objects including calibers up to 20 mm for bullets and up to 22 mm diameter for cartridge-cases.

The time of bullet side surface recording (3D image) for full evolvement of pristine bullet, caliber 9 mm, and cartridge case bottom surface (3D image), 10 mm diameter, is less than 2 min.

DAS provides easy and quick objects fixing into the scanning device.

DAS provides easy and quick objects fixing into the scanning device.

DAS is space-saved (desk-top-set variant) and electrically safety. The scanning device weight is less than 6 KG and power supply – 12V.